Машина непрерывной карбонизации биомассы

Производительность: 100-1500кг/ч

Источник тепла: все виды производства биомассы в сельском и лесном хозяйстве.

Применение: Подходит для карбонизации древесной стружки, опилок, щепы, рисовой шелухи, стеблей хлопка, соломы, соевого творога и т. д.

ВНЕДРЕНИЕ ПРОДУКЦИИ

Чтобы соответствовать требованиям по охране окружающей среды и защитить окружающую среду, компания предлагает новый тип роторного оборудования для непрерывной карбонизации. Это бездымное, экологичное, высокоэффективное и энергосберегающее оборудование. Это обеспечивает экономическое преимущество при решении серьезной проблемы загрязнения окружающей среды, вызванной традиционными печами для карбонизации, которые тратят ресурсы впустую.

Экологически чистая барабанная машина для непрерывной карбонизации использует очистку дымовых газов от карбонизации и превращает их в горючие газы, которые затем используются в процессе сжигания. Этот метод упрощает переработку и обеспечивает непрерывное производство в режиме 24/7 без загрязнения окружающей среды и выбросов. Эта высокопроизводительная машина также экономит затраты на рабочую силу и может похвастаться высокой степенью автоматизации и передовыми технологиями. Его пригодность для крупномасштабного производства подкрепляется высокой скоростью карбонизации, высокой скоростью производства углерода и энергосберегающим потреблением. Кроме того, это экологически чистый и высокоэффективный вариант карбонизации, обеспечивающий защиту окружающей среды.

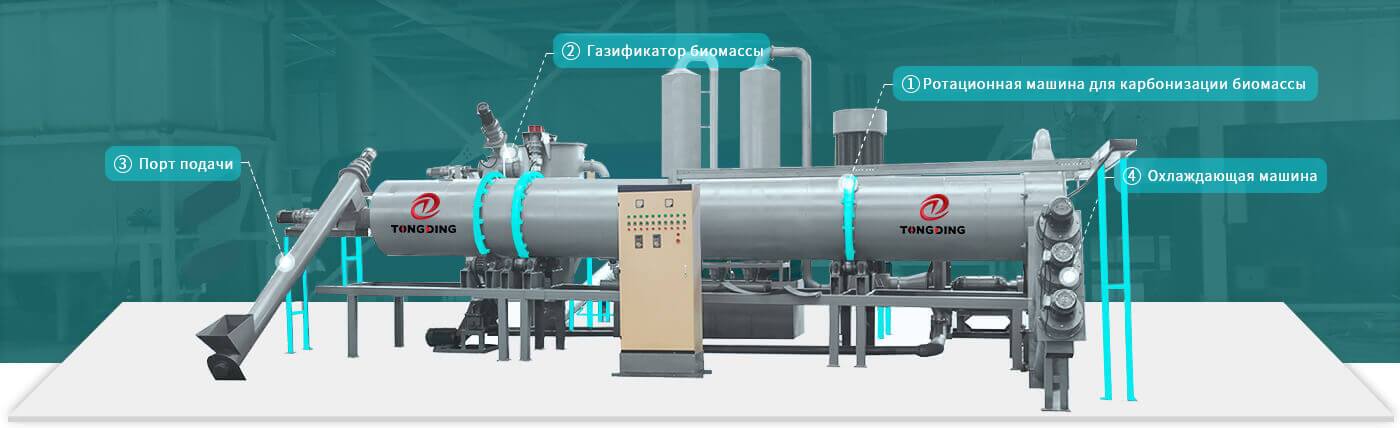

Справочник по макету

ПРИНЦИП РАБОТЫ

В газификаторе биомасса воспламеняется для получения дымового газа, который затем распыляется, охлаждается и очищается для получения чистого горючего газа, такого как окись углерода, метан и этан. Этот горючий газ используется в качестве источника тепла на ранних стадиях карбонизации для нагрева карбонизатора. После достижения заданной температуры можно начинать подачу и коксование. В процессе карбонизации дымовой газ распыляется, охлаждается и очищается, в результате чего в процессе сгорания образуется вторичный горючий газ. Этот процесс обеспечивает экономию энергии за счет самосгорания собственных дымовых газов. Кроме того, очищенный дымовой газ, образующийся во время производства, не имеет выбросов, что соответствует стандартам защиты окружающей среды для отходящего газа.

Производство во время карбонизации может достигать температуры в диапазоне от 500 ℃ до 700 ℃, а температуру можно регулировать в соответствии с характеристиками материала по мере необходимости.

Параметр

| Модель | Диаметр внутреннего слоя (мм) | Диаметр внешнего слоя (мм) | Длина барабана (м) | Объем углерода (кг/ч) | Мощность (кВт) | Размер (м) |

| TDC300 | 1000 | 1000 | 12 | 300 | 30-40 | 12*1.0*1.0 |

| TDC500 | 1300 | 1300 | 12 | 500 | 40-50 | 12*1.3*1.3 |

| TDC700 | 1600 | 1600 | 12 | 700 | 50-70 | 12*1.6*1.6 |

| TDC1000 | 1200 | 2000 | 12 | 1000 | 70-80 | 12*1.2*10*2.0 |

| TDC1500 | 1400 | 2200 | 12 | 1500 | 90-110 | 12*1.4*10*2.2 |

| TDC2000 | 1600 | 2400 | 12 | 2000 | 110-130 | 12*1.6*10*2.4 |

| TDC2500 | 1900 | 2700 | 12 | 2500 | 130-150 | 12*1.9*10*2.7 |

Hot Products:

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.