Линия по производству пеллет из биомассы

Производительность: 0,8-5 т/ч

Источник тепла: подходит для биомассы, природного газа, дизельного топлива, угля и т. д.

Применение: подходит для сушки и гранулирования щепы, пастбищ, опилок, соломы и других материалов и т. д.

ВНЕДРЕНИЕ ПРОДУКЦИИ

Энергия биомассы занимает четвертое место в общемировом потреблении энергии, уступая только углю, нефти и природному газу. Эксперты прогнозируют, что она будет играть все более важную роль в будущих устойчивых энергетических системах. Ожидается, что к середине этого века использование новых технологий для производства различных альтернативных видов топлива из биомассы будет составлять более 40% мирового потребления топлива.

Чтобы удовлетворить потребности рынка, наша техническая команда разработала и изготовила линию по производству пеллет из биомассы, способную производить пеллеты из биомассы с содержанием влаги от 35% до 56%. Эти материалы включают опилки, бамбуковую стружку, древесную стружку, ячменную солому, овсяную солому, пшеничную солому, ржаную солому, рисовую солому, рисовую шелуху, багассу, солому сорго, кукурузную солому, стебли бобов и стебли арахиса. Мы также предлагаем услуги по оптимизации процессов сушки и гранулирования на основе конкретных свойств материалов биомассы, масштабов производства, требований к применению, соображений стоимости, уровней автоматизации и условий на месте.

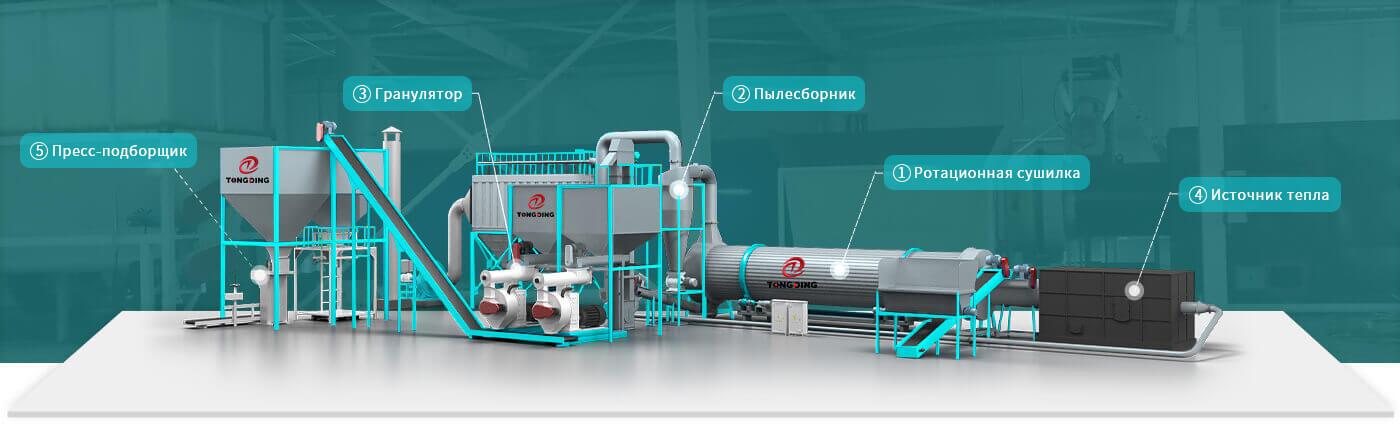

Справочник по макету

ПРИНЦИП РАБОТЫ

Используя принцип экструзии фильеры, гранулятор облегчает преобразование сельскохозяйственных отходов и сырья биомассы в твердое формовочное топливо, обеспечивая непрерывное и стабильное промышленное производство. Маршрут обработки включает однократную стадию сушки, за которой следует вторичное дробление, непрерывная подача и процесс, сочетающий смешанный процесс с регулируемой подачей. В результате скорость частицообразующего топлива достигает 98%, при этом насыпная плотность и плотность частиц остаются значительно высокими.

Применимые материалы

Могут использоваться деревья, древесные бревна, щепа, древесные опилки, кора, ветки, листья и подобные древесные отходы, солома (например, пшеницы, ячменя, ржи, овса), стебли (например, подсолнечника, кукурузы, хлопка, рапса), оболочка (кофе, сои, риса, арахиса, фундука, грецкого ореха), семена плодов, бумага-картон, отходы и мусор, строительные отходы; кроме того, они используются во многих продуктах энергетического лесоводства и энергетического сельского хозяйства (например, люцерна, хмель, конопля, трава-переключатель, слоновая трава). Пеллеты могут быть получены из одного продукта или путем смешивания нескольких продуктов (например, опилок, соломы и угольной пыли).

Параметр

| Модель | Производительность (т/ч) | Мощность двигателя (кВт) | Вес (т) | Площадь (м²) |

| TDBPK10 | 0.8-1.0 | 135 | 45 | 10×24m |

| TDBPK15 | 1.2-1.5 | 175 | 47 | |

| TDBPK20 | 1.5-2.0 | 210 | 55 | |

| TDBPK30 | 2.5-3.0 | 255 | 68 | 12×26m |

| TDBPK50 | 4.5-5.0 | 300 | 73 |

Hot Products:

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.