News

-

2025-10-29

2025-10-29Tongding Sand Drying Line – Advanced Solution for Kazakhstan’s Construction and Mining Sectors

Zhengzhou Tongding’s sand drying production lines are engineered to meet the specific demands of Kazakhstan’s growing construction and mining industries. Designed for extreme continental climate conditions, our systems deliver reliable performance in both summer heat and winter cold. Key Advantages for Kazakhstan: ✅ Extreme Climate Adaptation – Fully insulated system maintains efficiency from -35°C to 45°C ✅ Multi-Fuel Compatibility – Operates on natural gas, diesel, or electricity – Automatic fuel switching capability ✅ Russian-Kazakh Interface – Bilingual control system with local language support – Easy operation and maintenance ✅ High-Capacity Processing – Handles 10-80 tons per hour – Efficient moisture reduction from 20% to 0.5-1% Perfect for Kazakhstan’s Needs: 🏗️ Construction Projects – Urban development in Nur-Sultan and Almaty ⛏️ Mining Operations – Sand processing for resource extraction 🛣️ Infrastructure Development – Road construction and maintenance 🏭 Industrial Applications – Building materials production Technical Excellence: – Advanced heat recovery system reduces fuel costs by 35% – Automated moisture control ensures consistent quality – Dust collection system meets environmental standards – Modular design for quick installation Special Features for Kazakhstan: – Remote online technical support available – Custom configurations available Contact us today!

-

2025-10-27

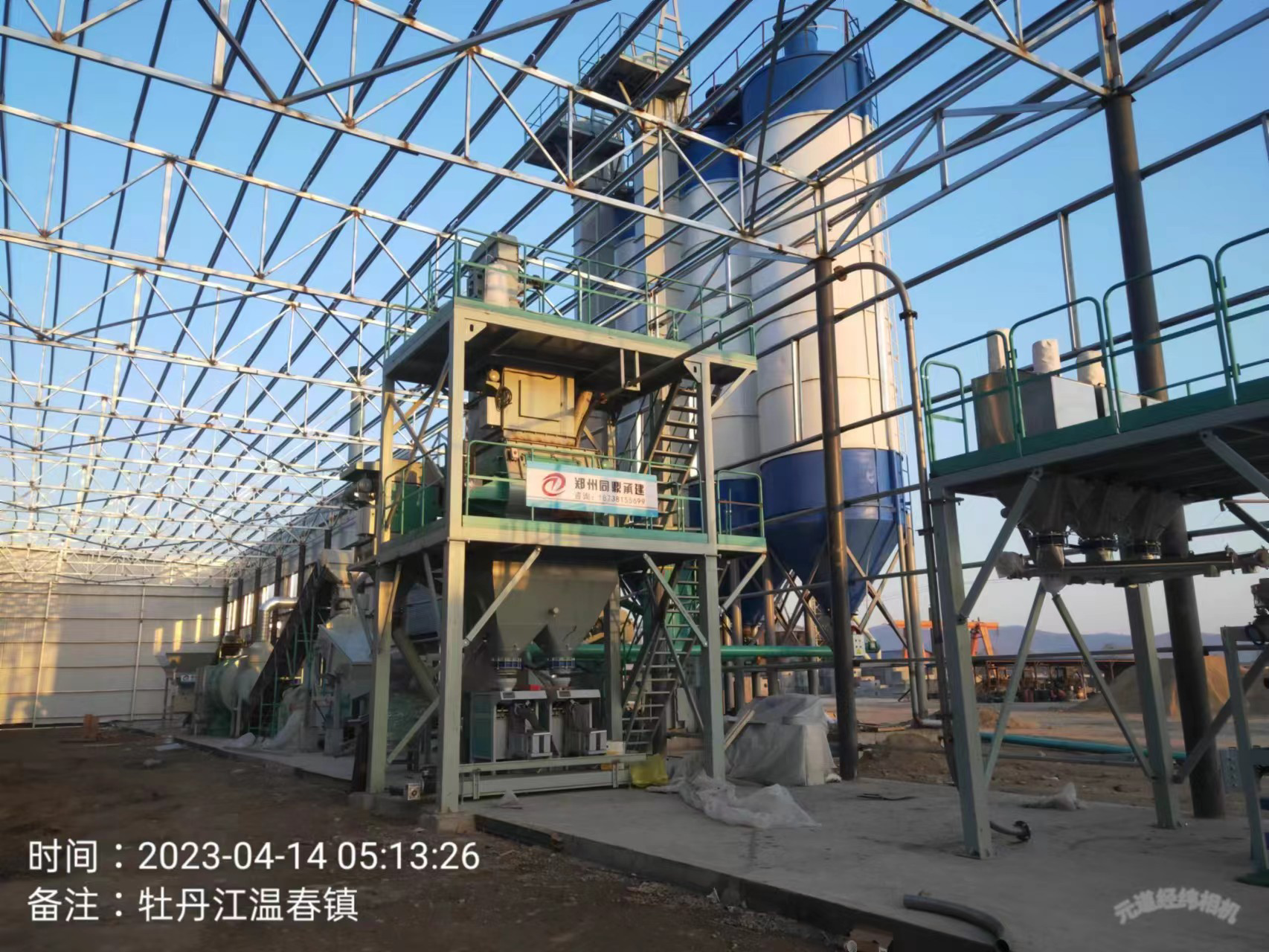

2025-10-27Zhengzhou Tongding Launches Advanced Dry Mortar Production Line with Enhanced Efficiency Features

Zhengzhou Tongding continues to lead innovation in construction machinery with its newly optimized dry mortar production line, delivering exceptional performance and reliability for global contractors. The latest upgrades focus on energy efficiency, operational simplicity, and adaptability to diverse job site requirements. Key Advantages of Tongding Dry Mortar Line: ✅ Intelligent Control System – Automated batching and mixing with precision up to 99.5% accuracy ✅ Energy-Saving Design – 30% reduction in power consumption compared to conventional systems – Advanced heat insulation maintains optimal mixing temperature ✅ Rapid Production Capacity – Output ranges from 5 to 50 tons per hour – Quick-change capability between different mortar formulations ✅ Durable Construction – Wear-resistant components ensure long service life – Minimal maintenance requirements reduce operational costs Industry Applications: 🏗️ Ready-mix mortar for large-scale construction 🏠 Small-batch production for residential projects 🛣️ Specialized mixtures for road and infrastructure work Technical Innovation: The newly mixing technology ensures homogeneous material distribution while reducing mixing time by 25%. The dust collection system meets international environmental standards with 99.2% filtration efficiency. Global Implementation: Recent successful installations across Southeast Asia and the Middle East demonstrate the system’s adaptability to various climatic conditions and local material characteristics. Contact us today!

-

2025-10-24

Tongding Dry Mortar Production Line Ships to Global Customers – Watch Our Loading Process!

We’re excited to share a behind-the-scenes look at our dry mortar production lines being carefully prepared for shipment to customers worldwide. Our recent loading video demonstrates the robust construction and professional packaging that ensures safe delivery and quick installation. Key Features Visible in Our Shipping Video: ✅ Modular Design – Pre-assembled sections for faster installation ✅ Robust Construction – Heavy-duty steel frames and components ✅ Professional Packaging – Weather-proof protection for long-distance transport ✅ Easy Installation – Clear marking and systematic organization Why Customers Choose Tongding: 🔹 Quick Setup – Operational within 5-7 days after arrival 🔹 Proven Performance – 98% on-time delivery rate to 30+ countries 🔹 Comprehensive Support – Installation guidance and training included 🔹 Energy Efficient – 30% lower power consumption than competitors Recent Global Shipments: → Vietnam – 15 tons/hour production line → Philippines – Compact system for urban construction → Saudi Arabia – High-capacity industrial plant Watch Our Loading Process Customer Feedback: “The equipment arrived in perfect condition and was operational within one week. Tongding’s professional loading and packaging ensured everything reached us without damage.” – Construction Manager, Middle East Contact Us for Your Project !

-

2025-10-23

2025-10-23Dominican Construction Delegation Visits Tongding Sand Drying Line in Zhengzhou

Zhengzhou Tongding’s simple dry mortar production line brings efficient and practical technology to support Ethiopia’s rapid infrastructure development. Designed for local conditions, this system helps Ethiopian contractors produce quality construction materials with minimal investment and maximum reliability. Key Advantages for Ethiopia: ✅ Power Adaptability – Handles frequent power fluctuations and generator operation ✅ Amharic/English Interface – Easy operation for local workforce ✅ Low Investment Cost – 60% more affordable than complex systems ✅ Quick Installation – Operational within 3-5 days ✅ Local Material Optimization – Works perfectly with Ethiopian cement and aggregates Perfect Applications: – Government housing projects across Addis Ababa and regional cities – Road construction and infrastructure development – Industrial park construction projects – Private real estate developments Special Features for Ethiopia: – Dust control system for urban environments – Low maintenance requirements – Easy-to-clean design – Online technical guidance. Contact us today!

-

2025-10-21

2025-10-21Tongding Dry Mortar Production Line – Ideal Solution for Kyrgyzstan’s Construction Industry

Zhengzhou Tongding’s dry mortar production line offers perfect solutions for Kyrgyzstan’s growing construction sector and harsh climate conditions. Designed specifically for regional requirements, our systems ensure high-quality mortar production with maximum efficiency. Key Advantages for Kyrgyzstan ✅ Cold-Climate Design – Maintains stable operation in low temperatures ✅ Bilingual Operation – Russian and Kyrgyz language interface support ✅ Power Adaptability – Handles voltage fluctuations common in regional grids ✅ Compact Layout – Suitable for limited factory spaces in urban areas ✅ Local Material Optimization – Compatible with Kyrgyzstan’s sand and cement varieties Perfect Applications: – Residential construction projects in Bishkek – Infrastructure development across regions – Road construction and maintenance works – Earthquake-resistant building initiatives Special Features for Kyrgyz Market: – Cold-resistant mixing system – Dust control technology for urban areas – Low maintenance requirements Contact us today!

-

2025-10-20

2025-10-20Tongding Sand Drying Line: Advanced Technology for Maximum Efficiency

Zhengzhou Tongding’s sand drying production line sets new standards in drying technology, delivering exceptional performance for construction and industrial applications worldwide. Our innovative engineering ensures reliable operation while significantly reducing operational costs. Core Advantages: ✅ High-Efficiency Thermal System Patented triple-pass design increases heat utilization by 40%, reducing fuel consumption substantially ✅ Smart Control Technology Fully automated PLC system with remote monitoring capabilities and real-time performance tracking ✅ Robust Construction Heavy-duty components withstand continuous operation in demanding environments with minimal maintenance ✅ Eco-Friendly Operation Advanced dust collection system captures 99.2% of particles, meeting strict environmental standards ✅ Flexible Configuration Modular design adapts to various production needs from 5 to 100 tons per hour capacity Technical Excellence: – Processes high-moisture sand from 15% to 0.5% moisture content – Compatible with multiple fuel sources: diesel, natural gas, biomass – Quick installation within 7-10 days – Energy recovery system reduces operating costs by 35% Global Applications: – Construction material manufacturing – Mining and mineral processing – Industrial sand production – Infrastructure development projects Special Offer: – Free project feasibility analysis – 1-year comprehensive warranty – Technical guidance – Worldwide installation support Contact Us today!