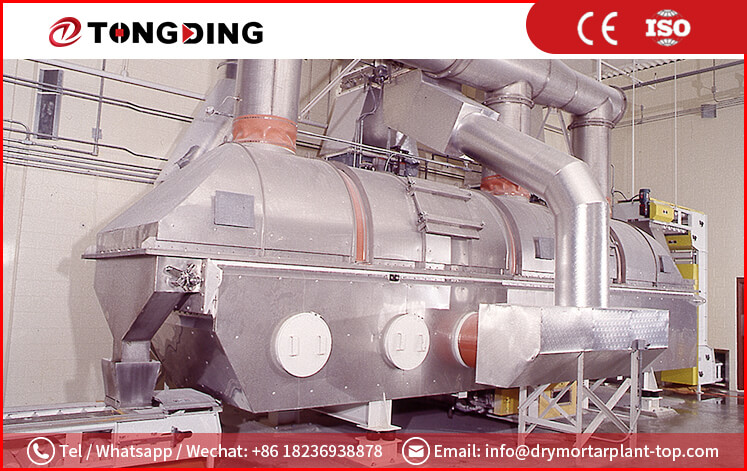

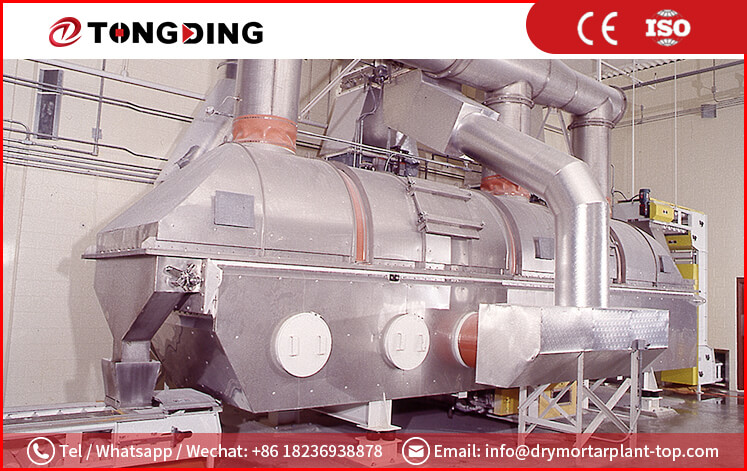

Product Introduction

The fluidized bed dryer, featuring a frame-type fission structure that is optimally designed, is a product of our advanced production technology and skillful manufacturing techniques, carefully selected raw materials, and industry-leading expertise. This machine finds widespread application in the drying, cooling, and humidifying processes of powder and granular materials in a variety of industries, including grain, chemical, pharmaceutical, food, dehydrated vegetables, minerals, and others. Examples of materials that can be processed with this dryer include magnesium sulfate, ferrous sulfate, borax, sodium borate, ammonium sulfate, slag, compound fertilizer, radish, soybean meal, distillers grains, seeds, refined salt, sugar, and more.

Working Principle

The feeder continuously supplies raw material to the feed inlet of the fluidized bed, which is then vibrated under the influence of an exciting force. The material leaps forward above the orifice plate, and the material particles become suspended in the hot airflow, achieving full contact via the dual effects of exciting force and uniform air. Meanwhile, the materials' flow creates intense turbulence, which enhances the heat transfer and mass transfer processes.

Parameter

|

Model |

Dimensions:L×W×H(m) |

Area of fluidized-bed(mm×mm) |

footprint(m²) |

|

TDOPP3×30 |

3505×1070×1700 |

300×3000 |

9 |

|

TDOPP3×45 |

5010×1070×1750 |

300×4500 |

10 |

|

TDOPP4.5×45 |

5010×1250×1750 |

450×4500 |

10 |

|

TDOPP6×45 |

5010×1450×1800 |

600×4500 |

11 |

|

TDOPP6×60 |

6510×1450×1850 |

600×6000 |

16 |

|

TDOPP6×75 |

8010×1450×1850 |

600×7500 |

17 |

|

TDOPP9×60 |

6510×2000×1850 |

900×6000 |

18 |

|

TDOPP9×75 |

8010×2000×1850 |

900×7500 |

20 |

|

TDOPP12×75 |

8010×2400×2050 |

1200×7500 |

22 |

|

TDOPP15×75 |

8010×2700×2250 |

1500×7500 |

24 |

|

TDOPP15×90 |

9510×2700×2300 |

1500×9000 |

26 |

Hot Products:

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.