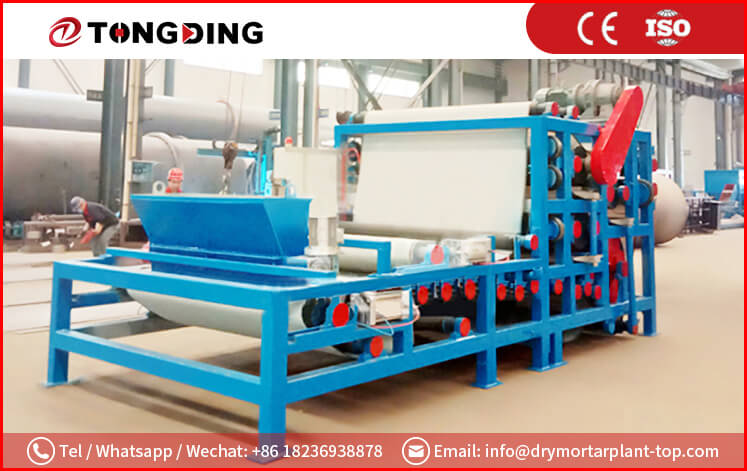

Bean Dregs Dehydration Drying Line

Capacity: 43.7-317.6 t/d

Heat Source:Suitable for biomass, natural gas, diesel, coal, etc.

Application: Widely used for drying bean dregs, brewer grains, potato residue, sweet potato dregs, cassava pulp, tapioca slag, etc.

Product Introduction

Bean dregs, which are the by-product of soy milk or tofu production, possess exceptional water and oil combining properties. Once processed, they offer several benefits such as a water content of approximately 90% and superior nutritional ingredients when compared to many inferior dregs. Additionally, their high crude protein content makes them an ideal feed for pig, chicken, duck, and other animals, especially during hot summers or high temperatures where they are prone to rotting and mildewing. Dry bean dregs also contain three times the amount of crude protein found in unhulled rice.

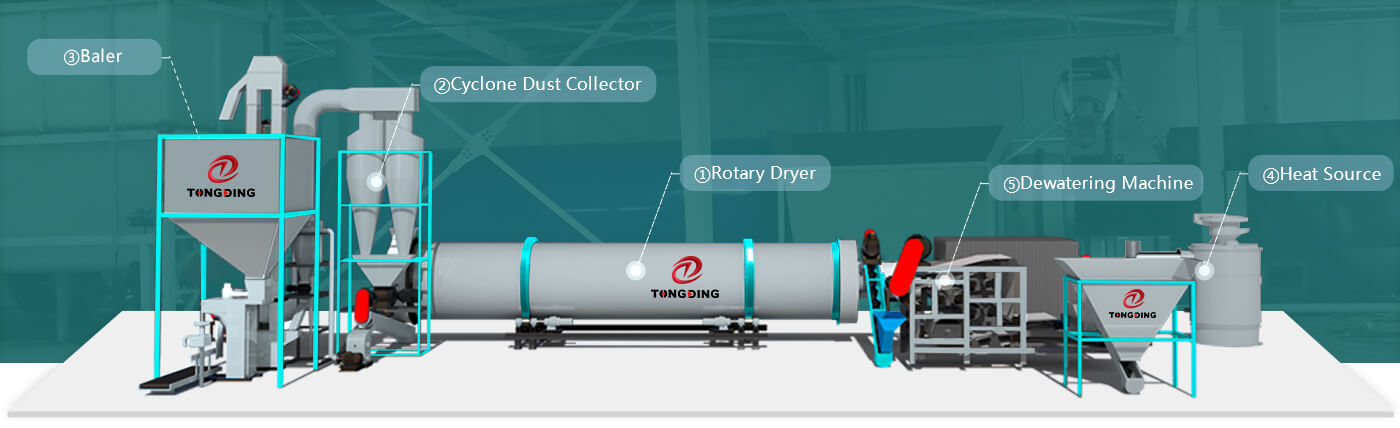

The bean dregs dryer comprises several components, including a heat source (hot blast stove or gas producer furnace), a material feeder (beater), a rotary drying roller, a discharger, an induced draft fan, a driving device, an unloader, and a power distribution cabinet. Wet bean dregs are dehydrated and scattered to some degree before entering the drying roller through the material feeder. Inside the roller, evenly distributed lifting and shoveling plates stir the bean dregs, which scatter and come into contact with the hot air in the drying area. This process accelerates the drying heat transfer and mass transfer. The air-inducing device pumps out wet air to prevent the material from getting damp again.

Layout Reference

Working Principle

The production line for the bean dregs dryer features a specially designed inner structure that ensures optimal drying of the bean dregs. This system incorporates a novel and unique sealing device, which is paired with an excellent thermal insulation system to reduce the coal consumption of the entire drying system. The integrated system provides exceptional sealing performance and is equipped with a perfect dust removal device, preventing any dust spillover and creating a favorable operating environment.

Parameter

|

Specification |

Input Capacity(t/d) |

Output(t/d) |

Evaporation Capacity(t/h) |

Total Power(kw) |

Total Weight(kg) |

Area |

Raw Material Moisture(%) |

Dried Material Moisture(%) |

Drying temperature(℃) |

|

TDFPZ257 |

43.7 |

25.7 |

0.75 |

55 |

25000 |

5m*20m |

(Mechanical dehydration to around 68%, and then dry by dryer) |

10% (adjustable) |

350-450℃ |

|

TDFPZ309 |

52.5 |

30.9 |

0.90 |

75 |

27000 |

5m*20m |

|||

|

TDFPZ446 |

75.8 |

44.6 |

1.30 |

95 |

28500 |

6m*22m |

|||

|

TDFPZ994 |

169.0 |

99.4 |

2.90 |

140 |

33500 |

8m*25m |

|||

|

TDFPZ109 |

186.5 |

109.7 |

3.20 |

170 |

38500 |

8m*25m |

|||

|

TDFPZ126 |

215.5 |

126.7 |

3.70 |

210 |

45000 |

10m*28m |

|||

|

TDFPZ154 |

262.2 |

154.2 |

4.50 |

260 |

60000 |

10m*30m |

|||

|

TDFPZ186 |

317.6 |

186.8 |

5.45 |

300 |

80000 |

10m*30m |

Hot Products:

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.