Spin Flash Dryer

Capacity: 5-35 t/d

Heat Source:Suitable for biomass, natural gas, diesel, coal, etc.

Application: Widely used in the dispersion and drying of granular, powdery, paste-like and filter cake-like false agglomerates in the chemical, pharmaceutical, building materials, food, feed, and other industries.

Product Introduction

The flash dryer finds wide application in the dispersion and drying of granular, powdery, paste-like, and filter cake-like false agglomerates in various industries such as chemical, pharmaceutical, building materials, food, and feed. This equipment is characterized by a small occupied area, low energy consumption, high thermal efficiency, and continuous mass production, making it highly desirable for many industrial processes.

The flash dryer body is equipped with a rotary cutting device, which subjects the dry material to shearing, rotating, collision, friction, and other forces to pulverize and refine it. As a result, the material becomes highly dispersed, leading to efficient and rapid water evaporation. The equipment comes equipped with an air filter to maintain the cleanliness of the hot air and to meet the hygiene requirements of the food industry. Cyclone separation and material collection are integrated into the machine, and a bag dust removal receipt is added to increase the material recovery rate, which can ultimately improve the economic efficiency of the enterprise.

Customization options are available to the user to meet specific needs, making this dryer a versatile and practical option for various industrial drying applications.

Adaptable material

The following are examples of materials suitable for processing using a flash dryer: 1.Foodstuffs such as soy protein, gelatinized starch, wheat sugar, wine trough, and wheat starch. 2.Organic compounds including Atrazine (pesticide pesticides), lauric acid, benzoic acid, bactericidal Dan, cellulose acetate, sodium oxalate, benzoic acid, and organic pigments. 3. Dyes such as antimony, black iron oxide, butyric acid, indigo pigment, titanium hydroxide, zinc sulfide, and various nitrogen dye intermediates. 4. Inorganic materials, including borax, calcium carbonate, copper sulfate, hydroxide, barium carbonate, antimony trioxide, iron oxide, various heavy metal salts, synthetic cryolite, and various metal hydroxides.

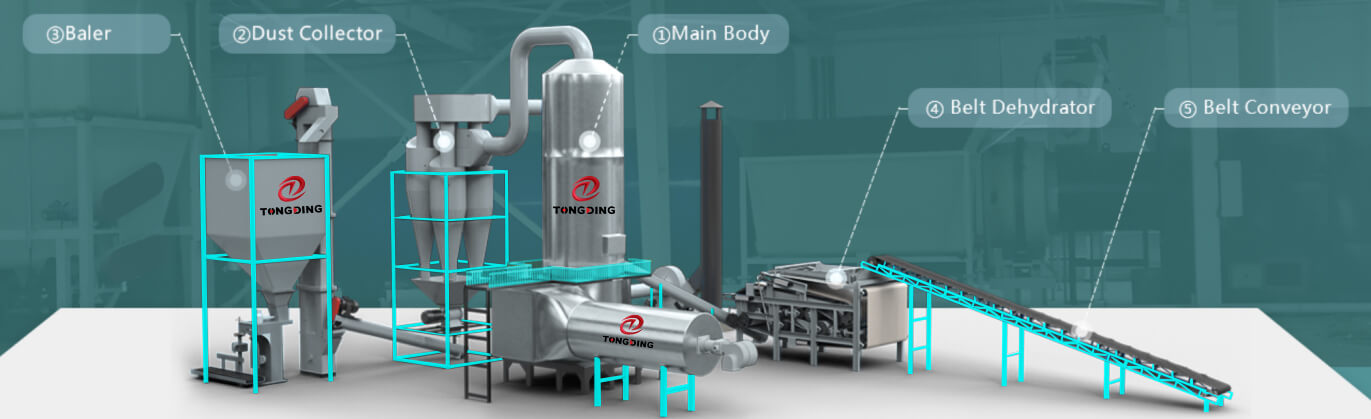

Layout Reference

Working Principle

The flash dryer is composed of various components including the main drying unit, feeder, heat source equipment (hot air furnace or steam), air filter, air blower, cyclone separator, bag filter, and induced draft fan. The hot air enters the dryer tangentially from the bottom and is driven by the agitator to form a powerful rotating air current. The paste-like material is introduced into the dryer through a screw feeder. The material is rapidly pulverized under the strong action of high-speed rotating stirring paddles, as well as through the combined impact, friction, and shearing forces. It is then fully exposed to hot air for thorough heating and drying.

The dehydrated and dried material rises with the hot gas flow, and the classification ring intercepts the larger particles. The smaller particles are discharged from the center of the ring to the outside of the dryer and are recovered by the cyclone separator and the dust collector. Any remaining damp material or bulk material is subjected to centrifugal force and falls to the bottom, where it is subsequently crushed and dried.

Parameter

|

Model |

Inner Diameter(mm) |

Air Volume(m3/h) |

Evaporation Capacity(kg/h) |

Total Power(kw) |

Max Height(m) |

Covering Area (m2) |

|

TDOPX15 |

200 |

350-500 |

12-17 |

10 |

4 |

15 |

|

TDOPX20 |

400 |

1150-2000 |

40-70 |

20 |

4.8 |

20 |

|

TDOPX28 |

600 |

2450-4500 |

80-150 |

40 |

5.8 |

28 |

|

TDOPX35 |

800 |

4450-7550 |

150-250 |

65 |

6.5 |

35 |

|

TDOPX40 |

1000 |

7000-12500 |

230-425 |

85 |

7.1 |

40 |

|

TDOPX52 |

1200 |

10000-20000 |

300-600 |

105 |

7.8 |

52 |

|

TDOPX80 |

1600 |

18000-36000 |

600-1000 |

150 |

8.8 |

80 |

|

TDOPX150 |

2000 |

28200-56500 |

1000-1500 |

230 |

10.1 |

150 |

Hot Products:

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.