Sludge Drum Dryer

Capacity: 5.4-80 t/h

Application: Widely used for drying sludge, animal manure, organic fertilizer, brewer's grain and other materials.

Product Introduction

Sludge is an industrial waste generated during the production process of municipal sewage treatment. Due to its high moisture content, high viscosity, high water holding capacity, and low calorific value, sludge is difficult to utilize in industry. To address this issue, TongDing Company conducted a series of technical research studies on the current market situation of sludge treatment and the characteristics of sludge in various regions.

As a result, TongDing Company developed a new generation of sludge rotary drum drying system that can reduce the moisture content of the drying product to less than 25%, achieving the standard of sludge landfill and further incineration processing conditions. The equipment technology has matured, with stable operation capacity, and it is very convenient to operate and maintain.

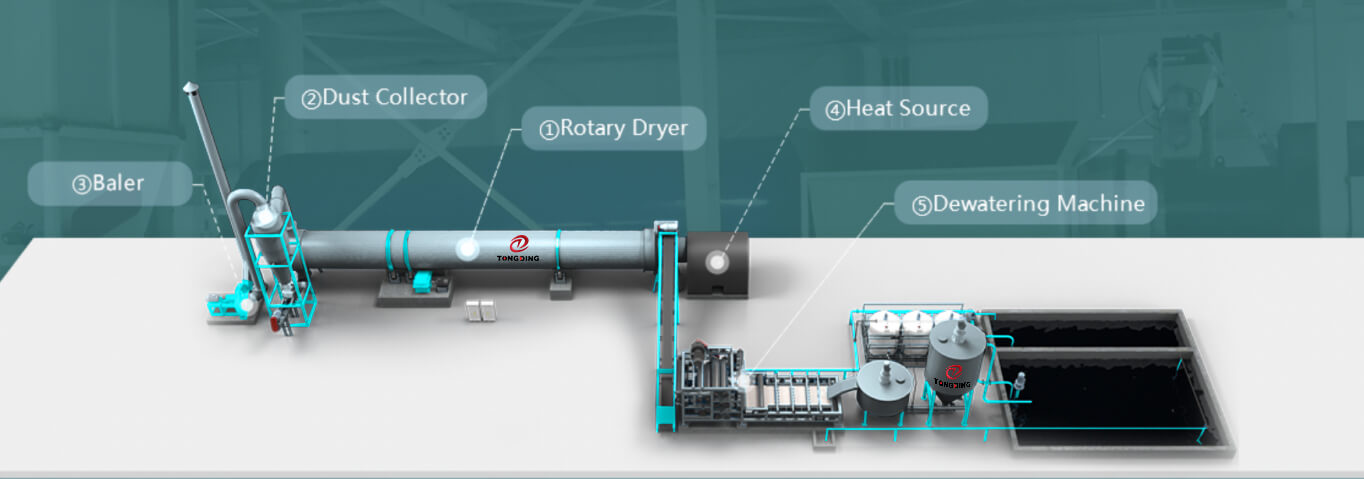

Layout Reference

Working Principle

The TongDing Sludge Drum Dryer is a comprehensive system that comprises several components, including the hot air furnace, scattering feeder, belt conveyor, rotary drum dryer, belt outlet conveyor, draught fan, dust collector, deodorant device, and electric cabinet.

The sludge drying equipment works in the following manner: Firstly, the wet sludge, which has a moisture content of about 80% and stickiness, enters the three-roller belt-dewatering machines to reduce the moisture content to 55-60%. After this, it enters the rotary drum dryer, where it passes through six drying work areas.

The first zone is the material feedstock zone, where the wet mud contacts high-temperature hot air to evaporate moisture rapidly. The material is in a large lifting flight angle and is introduced into the next working area without forming a bond. The second zone is the cleanup area, where the equipment repeatedly breaks and beats the material. The third zone is the main drying zone, where the wet mud has a loose granularity and conducts full heat exchange with the hot air. In the fourth zone, the mud particles are broken from 20-40mm to 10-20mm, and the moisture is further reduced. The fifth zone is the enhanced drying zone, where the broken small granular mud absorbs the heat of the hot air and discharges the moisture to prepare the material for discharge. Finally, the outlet material zone prevents the discharge of dust, and the material is rolled and glided to the discharge opening.

Throughout the process, the cleaning device reasonably cleans the mud adhered to the inner wall and prevents the wet mud from sticking. This enhances the heat exchange area and drying rate. The final moisture content of the sludge drops to about 20-25%, completing the drying process.

Parameter

|

Equipment |

Capacity(t/h) |

Evaporation moisture capacity(t/h) |

Total installation power(kw) |

Total Weight (kg) |

Spatial footprint(m²) |

Moisture content of raw material(%) |

Drop moisture content(%) |

Drying Temperature (℃) |

|

TDOPN5 |

5.4 |

1.2 |

65 |

25000 |

6m*18m |

55-60% |

20-25%(adjustable) |

850±100℃ |

|

TDOPN6 |

6.6 |

1.9 |

115 |

48000 |

6m*18m |

|||

|

TDOPN13 |

13.5 |

3.0 |

138 |

67000 |

8m*24m |

|||

|

TDOPN19 |

19.8 |

4.4 |

170 |

85000 |

10m*24m |

|||

|

TDOPN25 |

25.6 |

5.7 |

240 |

92000 |

10m*30m |

|||

|

TDOPN31 |

31.5 |

7.0 |

320 |

110000 |

10m*36m |

|||

|

TDOPN41 |

41.4 |

9.2 |

450 |

150000 |

10m*36m |

|||

|

TDOPN80 |

80.0 |

17.7 |

680 |

265000 |

10m*48m |

Hot Products:

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.