Straw Drying Production Line

Capacity: 44-260 t/d

Heat Source:Suitable for biomass, natural gas, diesel, coal, etc.

Application: Widely used for drying sawdust, wood chips, pasture, wood shavings, straw and other materials etc..

Product Introduction

The straw dryer is designed to effectively dry a variety of biomass materials, such as barley straw, oat straw, wheat straw, rye straw, straw, sorghum straw, corn straw, potato vines, and beanstalks (including soybean straw, broad bean straw, pea straw, cowpea straw, lupine straw, peanut vine, etc.). To optimize drying technology based on each biomass material's characteristic, production capacity, applying requirement, cost control, and operating convenience, our company provides the recommended product: the three-layer rotary drum dryer.

This equipment boasts a large production capacity, high efficiency, and energy-saving features, while occupying a small floor space. In comparison to standard dryer machines, it can save up to 30%-50% of energy, resulting in maximum energy and drying cost savings.

The straw rotary dryer comprises a heating device, feeding device, transport device, discharge device, dust extraction device, and other connecting parts. Material to be dried enters the rotary drum dryer, and the internal fins lining the inner wall of the rotary drum dryer lift it up as it rotates. Once the material reaches a certain height, it falls back down to the bottom of the rotary drum dryer and passes through the hot gas stream, thereby drying the material.

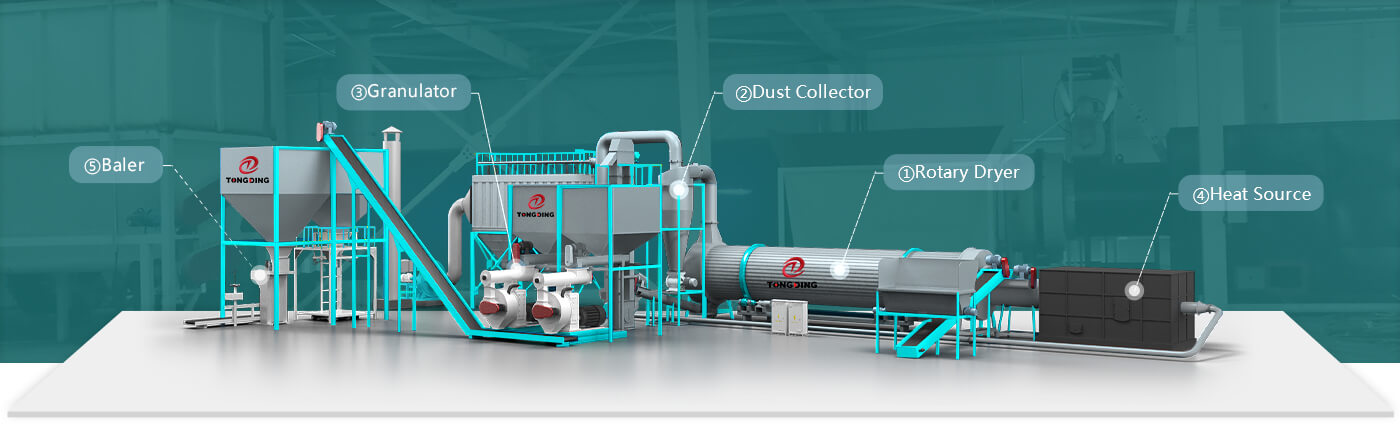

Layout Reference

Working Principle

The installation process of a crop straw rotary dryer involves several components, including a heating device, feeding device, transport device, discharge device, and dust extraction device, as well as various connecting parts. It is essential to ensure that the rotary drum dryer is sloped slightly during installation so that the discharge end is positioned lower than the material feed end. This design facilitates the conveyance of material through the rotary drum dryer via gravity.

The material to be dried is introduced into the rotary drum dryer and is lifted by a series of internal fins lining the inner wall of the drum as it rotates. Once the material reaches a sufficient height to roll off the fins, it falls back down to the bottom of the drum. During this descent, it passes through a stream of hot gas. This process continues until the material has been thoroughly dried. Overall, the operation of a crop straw rotary dryer is dependent on its various components working in unison to effectively dry the material.

Parameter

|

Model |

Input(t/h) |

Output(t/h) |

Evaporation Capacity(t/h) |

Total Power(kw) |

Total Weight(kg) |

Plant Area (m²) |

Initial Moisture(%) |

Final Moisture(%) |

Drying Temperature(℃) |

|

TDBPS108 |

1.53 |

1.08 |

0.45 |

34 |

22000 |

5m×15m |

40±5 |

15% (Adjustable) |

280±30℃ |

|

TDBPS203 |

2.89 |

2.03 |

0.85 |

45 |

28000 |

6m×22m |

|||

|

TDBPS367 |

5.2 |

3.67 |

1.53 |

78 |

40000 |

8m×16m |

|||

|

TDBPS468 |

6.63 |

4.68 |

1.95 |

90 |

45000 |

8m×18m |

|||

|

TDBPS511 |

7.24 |

5.11 |

2.13 |

105 |

50000 |

8m×20m |

|||

|

TDBPS629 |

8.91 |

6.29 |

2.62 |

125 |

60000 |

10m×20m |

|||

|

TDBPS741 |

10.5 |

7.41 |

3.09 |

140 |

68000 |

10m*24m |

|||

|

TDBPS857 |

12.14 |

8.57 |

3.57 |

155 |

76000 |

10m*24m |

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.