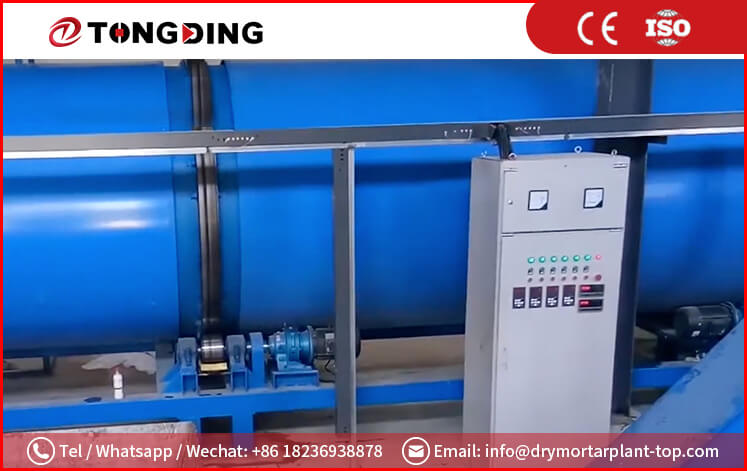

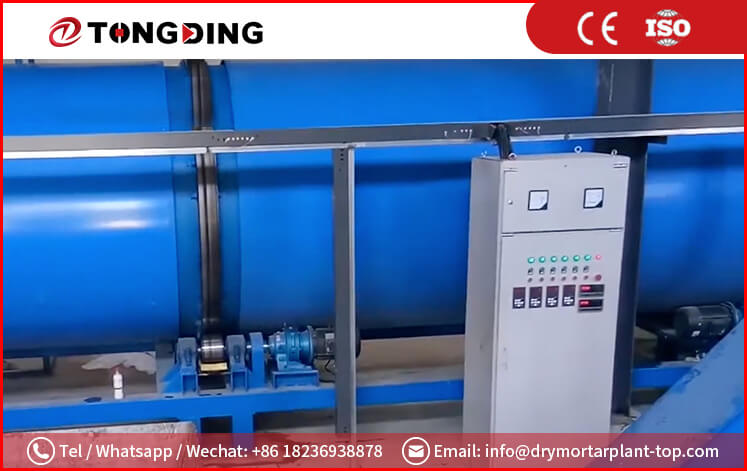

Paddle Stirring Drum Rotary Dryer

Capacity: 0.75-5.45 t/h

Heat Source:Suitable for biomass, natural gas, diesel, coal, etc.

Application: Widely used for drying sludge, bean dregs, starch residue, and sauce residue, spray corn bran, cassava dregs, brewer's grains, distiller's grains, straw, grass, organic fertilizer, etc.

Product Introduction

Zhengzhou TongDing machinery Co., Ltd has designed and manufactured a paddle stirring rotary dryer, also known as the paddle-harrow rotary dryer, to address market demands and issues with traditional rotary dryer designs. This dryer is suitable for high humidity materials with moisture content higher than 50% and relatively low viscosity, which the traditional dryer is not able to handle due to the ‘black hole’ phenomenon that occurs in the drum, reducing drying capacity and increasing energy consumption. The paddle rotary dryer sets high-speed spinning paddles to strengthen the crushing and separating functions. This leads to an increased contact surface area between particles, greatly improving the heat transfer and vaporization rates. Practical tests have shown that the unit vaporization capacity per hour of the paddle rotary dryer can reach 25-60kg/m2, which is 1-2 times that of traditional rotary dryers. As a result, output is raised by 50% and fuel consumption is reduced by 30%. Furthermore, the drying efficiency and footprint are increased by 40%.

This dryer is suitable for drying high-moisture materials with 50%-85% moisture content, such as sludge, bean dregs, starch residue, and sauce residue, as well as spray corn bran, cassava dregs, brewer's grains, distiller's grains, straw, grass, organic fertilizer, and chicken/beef feces. We optimize the drying process according to the specific properties of different biomass materials, production scale, application requirements, cost control, automation level, and site conditions.

Working Principle

Materials with a moisture content ranging from 50% to 85% are fed into the roller conveyor for downstream drying. The inner shoveling plate constantly scatters and moves the materials in a spiral forward method. This movement takes place through three layers, namely the inner, middle, and outer layers, facilitating heat exchange between the materials and hot air.

Parameter

|

Model |

Input (t/h) |

Output (t/h) |

Evaporation Capacity (t/h) |

Total Power (kw) |

Total Weight (kg) |

Plant Area (m²) |

Initial Moisture (%) |

Final Moisture (%) |

Drying Temperature (℃) |

|

TDOFJ107 |

1.82 |

1.07 |

0.75 |

32 |

15000 |

5m*15m |

50±5% |

15% (Adjustable) |

350±30 |

|

TDOFJ128 |

2.18 |

1.28 |

0.9 |

40 |

17000 |

5m*15m |

|||

|

TDOFJ185 |

3.15 |

1.85 |

1.3 |

55 |

21500 |

6m*16m |

|||

|

TDOFJ224 |

3.81 |

2.24 |

1.57 |

95 |

26500 |

8m*18m |

|||

|

TDOFJ280 |

4.76 |

2.8 |

1.96 |

95 |

26500 |

8m*20m |

|||

|

TDOFJ324 |

5.51 |

3.24 |

2.27 |

100 |

28500 |

8m*20m |

|||

|

TDOFJ372 |

6.33 |

3.72 |

2.61 |

125 |

37000 |

10m*20m |

|||

|

TDOFJ447 |

7.6 |

4.47 |

3.13 |

145 |

41000 |

10m*22m |

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.