Special Cassava Dregs Drying Line

Capacity: 43.7-317.6 t/d

Heat Source:Suitable for biomass, natural gas, diesel, coal, etc.

Application: Widely used for drying potato residue, sweet potato dregs, cassava pulp, tapioca slag, and other starch residues.

Product Introduction

Cassava pulp and potato residue are the primary by-products generated during the production of starch and alcohol. With a moisture content of about 80%, these residues exhibit high viscosity and pose a challenge for traditional drying processes. Drying at high temperatures results in the gelatinization of slag starch, which clogs material particles pores, turns the surface yellowish-black, and affects the marketability of the dry residue. Conversely, drying at low temperatures cannot reduce the moisture content to less than 15%, leading to sticky walls, gelatinization, and agglomeration of the dryer, which hinders normal production and results in dissatisfied customers.

To address these challenges, Dingli has developed a starch slag dryer based on the characteristics of raw materials such as cassava and potato slag. The dryer uses "mechanical dehydration + drum drying + pulse air drying" special Chinese patent technology, which can dry all types of potato residue below 10% in a single pass. This equipment has undergone multiple production runs and delivers perfect color, good quality, energy-saving, and environmentally friendly production. Its safe and stable operation has earned it praise from many new and old customers.

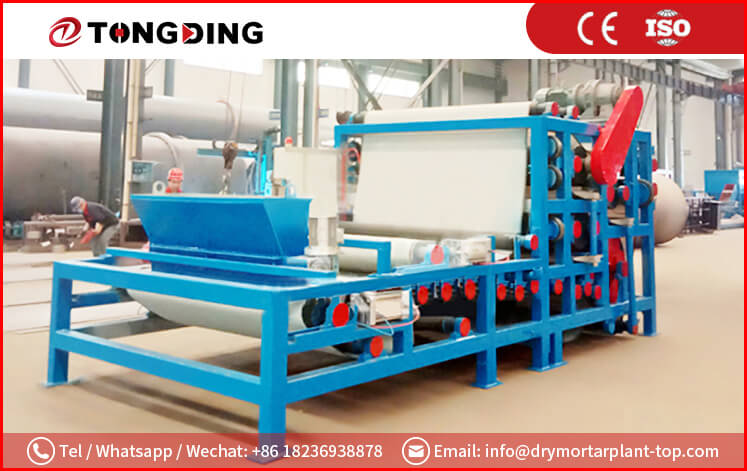

Layout Reference

Working Principle

Material flow: The material, which has a moisture content of 75-85%, is first treated with a specialized dehydration machine to remove a portion of its moisture. This process results in the removal of approximately 68% of the moisture. The partially dehydrated material is then transported to the downstream drying section via a screw conveyor.

Inside the dryer, the material is constantly taken and scattered by the inner shoveling plate, and it moves in a spiral forward motion. The mixing blade device inside the dryer fully stirs and crushes the material, allowing for complete heat exchange between the material and the hot air. This results in the rapid evaporation of water vaporization, reducing the moisture content to about 35%. The material is then discharged by the screw conveyor and sent to the semi-wet material crusher, which crushes the material into particles below 1mm in size.

After crushing, the material is subjected to pulse air-drying, during which the moisture content is quickly reduced to 10% using a cyclone discharger. The dry powder is recovered using a pulse bag dust collector, and the exhaust emissions meet the national standard requirements. This completes the entire drying process.

To prevent the material from adhering to the cylinder wall, a drum cleaning device is installed inside the dryer.

Airflow: The air is drawn into the hot blast stove for combustion heating by the hot blast stove fan. The temperature of the air reaches 600-850℃ before being drawn into the dryer by the induced draft fan, where it is absorbed by the material and evaporates the water. The material undergoes heat exchange and drying. Once the temperature decreases to 55-85℃, the air is discharged out of the dryer.

Wet dust is discharged in a standard manner using the cyclone, and the pulse dust collector purifies and emits it.

Parameter

|

Specification |

Input Capacity(t/d) |

Output(t/d) |

Evaporation Capacity(t/h) |

Total Power(kw) |

Total Weight(kg) |

Area |

Raw Material Moisture(%) |

Dried Material Moisture(%) |

Drying temperature(℃) |

|

TDFPZ257 |

43.7 |

25.7 |

0.75 |

55 |

25000 |

5m*20m |

(Mechanical dehydration to around 68%, and then dry by dryer) |

10% (adjustable) |

350-450℃ |

|

TDFPZ309 |

52.5 |

30.9 |

0.90 |

75 |

27000 |

5m*20m |

|||

|

TDFPZ446 |

75.8 |

44.6 |

1.30 |

95 |

28500 |

6m*22m |

|||

|

TDFPZ994 |

169.0 |

99.4 |

2.90 |

140 |

33500 |

8m*25m |

|||

|

TDFPZ109 |

186.5 |

109.7 |

3.20 |

170 |

38500 |

8m*25m |

|||

|

TDFPZ126 |

215.5 |

126.7 |

3.70 |

210 |

45000 |

10m*28m |

|||

|

TDFPZ154 |

262.2 |

154.2 |

4.50 |

260 |

60000 |

10m*30m |

|||

|

TDFPZ186 |

317.6 |

186.8 |

5.45 |

300 |

80000 |

10m*30m |

Hot Products:

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.